Brass, a timeless alloy revered for its lustrous appearance, undergoes a transformative phase and over time becomes known as patina. In the world of metal aesthetics, brass patina represents the exquisite marriage of age and character, to give the best aesthetic output. At its essence, brass patina is the result of a natural oxidation process. This gives a reflection of the material’s resilience, a visual echo of its enduring quality.

The importance of achieving brass patina extends beyond mere aesthetics. It provides testament to the passage of time through years of use and exposure.

From the chemical reactions responsible for its formation to practical DIY applications, it requires knowledge and practice to master the art of achieving brass patina. Join us on a journey through time and technique, to explore the intricate world of brass patina, unraveling its definition, understanding its significance.

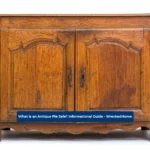

What is BRASS PATINA?

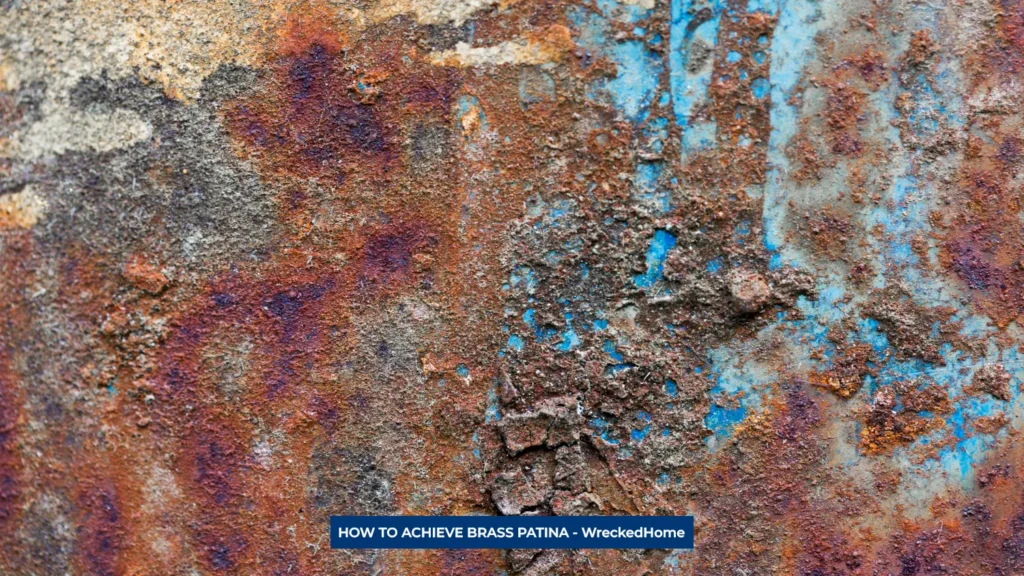

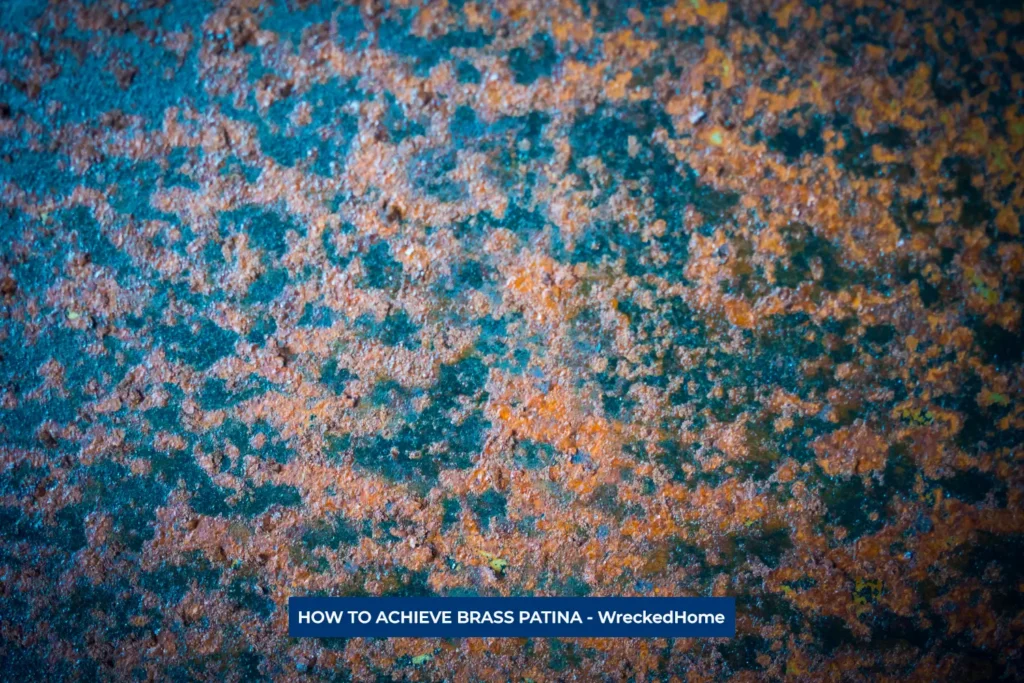

Brass patina is the captivating result of the natural aging process that is composed primarily of copper and zinc. Over time, as brass interacts with its environment, a chemical reaction known as oxidation results in a greenish-brown layer that characterizes patina.

The composition of brass typically consists of 60-70% copper and 30-40% zinc that undergoes oxidation when exposed to air and moisture. This oxidation process is accelerated by the presence of zinc which boosts the further formation and characteristic patina layer.

The natural aging process of brass is polished shine to the rich, nuanced hues of patina. As the surface weathers, a protective layer of corrosion develops and serves as a testament to the enduring quality and resilience of the brass.

The significance of patina on brass extends an aesthetic feature telling a story of time, use, and the enduring beauty of transformation.

Factors Influencing Brass Patina

Patina Brass, that unique and sought-after weathered appearance, contributes to the gradual transformation of the alloy’s surface. There are some of the factors that affect to harness the beauty of patina. Here are five key factors that contribute in the development of brass patina:

- Atmospheric Conditions: The environment in which brass is placed has a great impact on patina formation. Exposure to varying atmospheric conditions, such as humidity, temperature fluctuations, and air quality, ensure the speed and intensity of the patina process. In regions with high humidity, brasses have the ability to from higher quantities of patina that induces by increased moisture in the air.

- Exposure to Moisture: Moisture is a catalyst for the oxidation process that results from the patina. Whether it’s outdoor elements like rain or indoor factors like high humidity levels, there is a high level of moisture that induce chemical reactions between the copper and zinc in brass. It results in fostering the gradual development of patina layer over the brass.

- Chemical Reactions: The composition of brass itself contributes to patina with oxygen in the air, forming copper oxide. The presence of other airborne substances, such as sulfur compounds, is a primary component to influence the color and texture of the patina.

- Oxidation Process: The formation of Patina on brass is the process of oxidation. Oxygen interacts with the surface of the brass that accumulates over time, they create the distinctive colors and patterns characteristic of patina. It has different color shades that range from vibrant greens to deep browns.

- Interaction with Airborne Substances: There are various substances in the air that impact the formation of patina. For example, exposure to pollutants, industrial emissions, or even airborne salts in coastal areas contribute to the uniqueness of each patina.

Techniques for Accelerating Brass Patina

To achieve the patina brass you need to induce art full process, and for those eager to expedite the natural aging of brass, there are various techniques. With use of advanced techniques that offer a shortcut to the coveted weathered appearance; it is easy to get patina. Here are five effective methods that you can follow along with step-by-step instructions to get this process at a fast speed:

1. Natural Exposure: For oxidation processes, it is necessary to have natural exposure for achieving patina brass. You must offer a humid environment

Steps:

- Select a location with varying atmospheric conditions, that have high level exposure to air and moisture.

- Place the brass item in an outdoor setting, such as a garden or balcony, where it can easily interact with moisture.

- Keep brass in its natural environment for long time and check it periodically for the development of patina.

- Patina intensity will vary based on environmental factors, so you can do necessary adjustments.

2. Vinegar and Salt Solution: An acidic environment fosters the patina formation. You can create it artificially with the use of vinegar and the corrosive nature of salt. To achieve it you need to do the following things.

Steps:

- Take a container; and mix equal parts white vinegar and table salt to create a solution.

- Submerge the brass item in the solution that allows formation of patina.

- Allow the brass to soak for several hours, and keep an eye to check interval after interval.

- Remove the brass and rinse it thoroughly with the use of water.

- Pat dry with a Microfiber Cloth and you will see a layer of patina on the surface.

3. Ammonia Fuming: Ammonia fuming is a method that utilizes the fumes of household ammonia for formation of the patina. You can follow the steps below to achieve patina.

Steps:

- In a seal-able container, put a small dish that has household ammonia.

- Position the brass item above the dish, ensure it does not touch the liquid.

- Now seal the container, and allow ammonia fumes to surround the brass.

- Let the brass item fume for several hours, keep checking it from time to time.

- Once the desired patina is achieved, now remove the system and allow ventilation.

4. Application of Patina Solutions: There is a patina solution that is available in commercial settings. It provides a controlled and efficient means that speeds up the brass patina formation and offers a variety of colors and effects.

Steps:

- Choose a patina solution based on the desired outcome that impacts the resulting color (e.g., green, brown, or blue patina).

- The surface of patina should be clean and free from oils or contaminants.

- Apply the patina solution evenly with the help of a brush or spray bottle.

- Allow the solution to sit on the brass for time then rinse it with water.

- There will be a layer of accelerated patina.

5. Salt and Ammonia Combination: Combining salt and ammonia creates a potent solution that gives a large amount of patina. There is a controlled condition that impacts the quantity of patina.

Steps:

- Mix equal parts of salt and household ammonia to make a solution that you apply with a brush or sponge.

- Allow the brass to sit for a specified time and monitor it until the formation of patina.

- Rinse the brass with water and leave it to dry.

Maintenance and Preservation Tips for Brass Patina

Achieving the desired brass patina is a rewarding process that requires careful attention, specified time and consideration. Here are essential tips to ensure the longevity and continued allure of your patina:

- Protective Coating: Apply a clear protective coating, such as a wax or lacquer that is shielding the patina from further oxidation and environmental influences.

- Gentle Cleaning: When cleaning brass with patina, use a soft, lint-free cloth or sponge dampened with mild soapy water for cleaning surface. To avoid any scratch don’t use the abrasive cleaners or scouring pads.

- Avoid Harsh Chemicals: Steer clear of harsh chemicals and abrasive cleaning agents to accelerate oxidation. It erodes the patina.

- Periodic Inspection: Regularly inspect brass items with patina to avoid from potential deterioration. If you notice any issues, then address promptly by following the cleaning or preservation methods.

- Controlled Environment: Control the environment in which there is extreme humidity, direct sunlight, or fluctuating temperatures.

- Handling with Care: Handle brass items with patina carefully. Use soft gloves to protect the surface from oils and fingerprints.

- Reapplication of Protective Coating: Periodically reapply the protective coating. This ensures ongoing preservation and guards against the natural aging process.

By incorporating these maintenance and preservation tips into your care routine, you can get the transformation of brass to patina.

Conclusion

In the alchemy of metalwork, the journey to achieve and preserve brass patina requires time and suitable environment. The techniques discussed, from natural exposure to chemical interventions, are key to assist the professional to craft their own patina masterpieces.

As we dive into the formation of brass patina, a responsibility emerges—to safeguard and nurture this weathered beauty. For this need, follow our practical tips to protect the integrity of the patina, allowing it to withstand the test of time with grace.

If you have a project that requires a professional, don’t hesitate to hire one. Find A Pro Near You Here!

FAQs

What is the patina effect on brass?

Brass’s patina effect is a unique greenish hue resulting from the oxidation of copper within the alloy. Unlike copper, which leans towards a blue patina, brass exhibits a more distinct green coloration as it weathers. This weathered effect adds character and depth to brass surfaces that create a visual impact.

What is the difference between brass and patina brass?

Patina brass is essentially untreated brass that allows the development of fingerprints and smudges over time. The resulting tarnish is named as a patina that gives a unique charm of the metal.

How long does it take brass to patina?

Left to its natural course, it takes approximately 2 years to form patina. However, for those seeking a quicker transformation, there are some techniques that encourage brass to tarnish almost instantly.