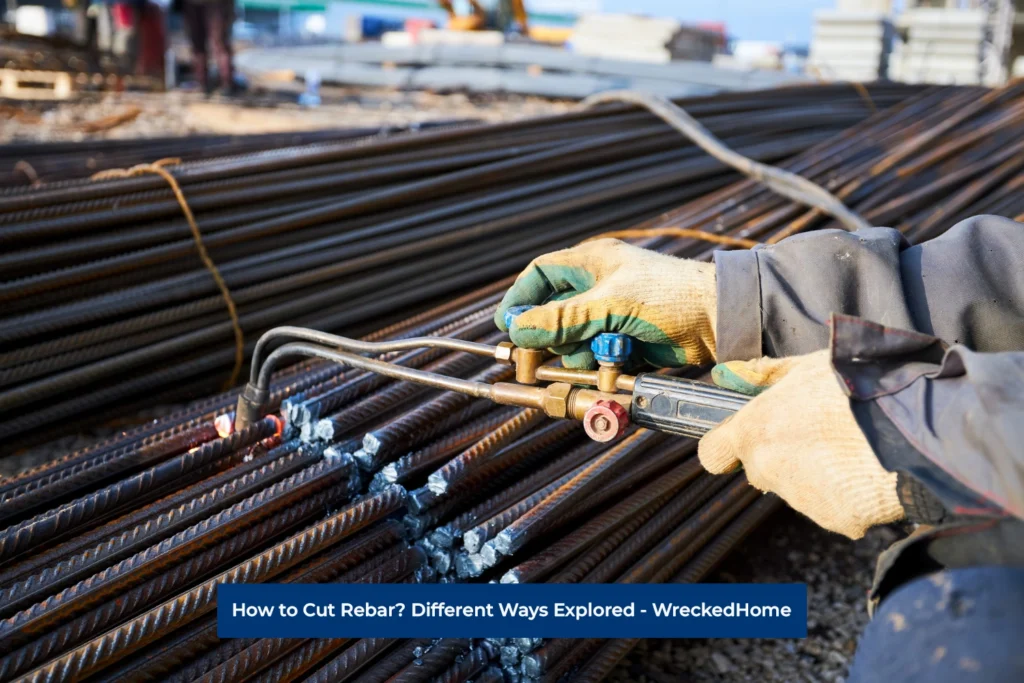

Do you want to learn how to cut rebar? On construction sites, rebar is popular. On those sites, you will notice that rebar is cut several times a day. Because of its popularity, we decided to write this article all about rebar cutting.

How to Cut Rebar?

Rebar is also known as reinforced steel. It contains 95 percent recycled material which makes it extremely environmentally friendly. Some types of rebar are also made of aluminum or composite.

They are used on construction sites for various reasons. The main purpose of rebar is to give support to the concrete structures. It prevents cracks in any concrete structure. So, masons used them a lot. Also, DIY enthusiasts may also need to use rebars. This can be for multiple reasons. They use it in landscaping, gardening, furniture making, shelves, and in different art projects.

Rebars come to construction sites in a standard sizes. One type of bar is around 60 feet. This is extremely big. With that being said, you need to know how to cut rebar to fit it in your projects.

You will need to make a lot of cuts on this metal bar. You should cut its corroded part, or bend it to fit in with other rebars.

Before cutting it, you need to prepare. This includes preparing yourself to cut the rebar and taking different precautionary steps.

Preparing Yourself to Cut the Rebar

Cutting rebar is not easy as a piece of cake. It requires expertise, proper setup, and different precautionary steps. You should be mentally and physically prepared before doing this task. To get ready, you should keep these points in mind:

- You should wear goggles and gloves before starting the project. Wear a mask on your face, and have a long shirt and pants for the project. It will keep you safe while cutting the rebar.

- Have a large workspace. Because rebars are long, you need enough space to cut them.

- Check the surroundings of your workspace. There shouldn’t be any flammable things. Otherwise, the flames of the rebar can cause accidents.

- You should accurately measure your rebar. Mark the points where you want to cut. Also, if you want to make a curve on your metal bar for bending it, you should draw it. Use chalk or wax crayon for this.

- The rebar can move in different places while you are cutting it. So, you should secure it properly. For this, you can use clamps. Or, you should put a firm foot on your rebar.

Do these five things before learning how to cut rebar. Now, we are going to discuss a few tools that you can use for this purpose.

Tools to Cut Rebar

There are different tools for cutting rebar. What are these? We will be discussing them below.

Circular Saws (Cut Rebar)

A lot of experts prefer circular saws to cut the rebar. They are popular because they are inexpensive and can easily cut the metal rebar.

It goes through the bar as smooth as a hot knife goes through butter. This means you can accomplish your cutting task in little time with little effort.

Moreover, it is a long-term investment because this saw can last for a long time. It is expensive but the long life and the low price of the blade make it an economical choice.

A lot of masons recommend the use of diamond blades in circular saws. This is because the diamond blade can easily cut the rebar. Moreover, it doesn’t cause the issues that a dull blade can cause.

But, you need to have some practice with this tool before cutting the rebar. Remember, it ignites sparks that can fly in your work space. So, you need to take the precautionary steps that we mentioned earlier.

Angle Grinders (Cut Rebar)

In learning how to cut rebar, you should know about angle grinders. These are used when you have a tight workspace or want to make a few cuts on your rebar.

They provide harsh and quick cuts to your metal. You can have neat cuts on multiple rebars with the help of this tool.

You can line up different rebars and mark them where you want to cut them. Then, use a metal cutting abrasive disc.

Change the settings of your angle grinder to set its speed to the maximum. After that, switch on this tool. Slowly plunge it into your rebar. You should make sure not to add any pressure on it. The tool will do its task easily.

But, you can face different issues with this tool too. It causes flames, dust, and smoke which can be harmful to your respiratory system.

Moreover, the tool can experience kickbacks. This means the blade can jam into the material you are cutting. So, you can drop it on your foot or leg too.

So, keep this tool as your last option.

Bandsaw (Cut Rebar)

A lot of people don’t give props to bandsaws just like they forget to give props to the chainsaw. Many think a bandsaw is not efficient enough to cut the rebar. But, this is not the truth.

This tool can provide precise, neat, and bulky cuts on your rebar. People usually dismiss the bandsaw because of its bulky size. But, I assure you that it is one of the most efficient rebar cutting tools.

The best thing is they don’t produce much vibration and sparks. So, you don’t need to worry about fire while using this tool.

This tool is slow to cut the rebar, however. You can only cut one rebar at a time with a bandsaw. So, it is not ideal for construction sites. DIY enthusiasts and homeowners can use it for small projects.

Hacksaw (Cut Rebar)

A Hacksaw can be used for small projects. But, it can be used for learning how to cut rebar. When you need to do less rebar cutting, you can go for this tool.

You should clamp your rebar safely before cutting it with the hacksaw. Then, make small cuts with this tool on your steel. When the grooves form on your bar, you should make long and steady cuts on the metal bar.

But, you need a lot of time and strength to use the hacksaw. You should have strong arms because cutting the rebar with this tool can take a lot of strength.

Moreover, this tool is not electrically activated. So, you have to handle it manually. This can make you tired. That’s why you should use it for small projects only.

Chop Saw (Cut Rebar)

The chop saw has a non-toothed, abrasive blade. This blade is mounted on a rotating arm. In learning how to cut rebar, this tool is ideal to use.

It can cut multiple rebars at one time and can produce clean and precise cuts. It has a large blade whose size is a minimum of four inches. So, you can get long cuts easily.

Moreover, the saw can cut the rebar at a 90 angle. You just need to keep it on the high speed while cutting, and you will get the desired result.

The only drawback of this tool is it is expensive and difficult to transport. This tool is also noisy. So, it can irritate you and your neighbors.

Reciprocating Saw (Cut Rebar)

This saw is also known as a tooth saw and contains different types of blades. These blades are high-quality diamond grit blades, carbide, or bi-metal blades.

A lot of experts suggest that you should go for a blade with carbide teeth. This blade with a back tooth design will have a long lifespan and can give satisfying results.

You should switch your saw’s mode from straight to oscillating. Also, keep the speed of the saw low to get the desired results.

The blade has different teeth per inch (TPI) which is best for different types of metal. You should choose 20 to 25 TPI if your metal is thin. For medium-sized metal, you should choose 10 to 17 TPI. For heavy ones, go for 5 to 7 TPI.

The negative aspect of this saw is it vibrates a lot and it is difficult to handle. Your arms can get tired after using this saw for a long time because of its vibration.

Bolt Cutters (Cut Rebar)

Bolt cutters are not an ideal option for cutting rebar, but it is still a popular one. It can slice through the metal with minimum effort.

You just need to put the cutter on the mark of the rebar. Then, close the handles. It will start cutting.

But, you can’t get a neat cut through this tool. The cut can have sharp edges so you should be careful. Don’t use it in large projects or where you want precision.

The bolt cutter can cut small-diameter rebars. But, for cutting ½ inch bar, you can have a heavy-duty cutter too.

Rebar Cutting Machine (Cut Rebar)

This machine is the most acceptable approach for those learning how to cut rebar. Its electric bar cutters can give you precise cuts, and it is a straightforward method.

This machine weighs around 900 to 1300 lbs. So, professionals use it on the construction site.

It has a cutting clutch, support brackets, and lifting rings. The cutting clutch helps the operator regulate the action. The support brackets can keep the cutting process safe. The lifting ring can enable the machine to move it wherever you want it.

There are different varieties of this machine, and they all are ideal for different types of projects.

Conclusion

Learning how to cut rebar is not easy. However, we don’t believe that you have to be intimidated by it either. With safe practices, you should be able to do this.

If you have a project that requires you to cut rebar, please hire a professional. Find A Pro Near You Here!